Hydraulic Shearing Machine Price in Gujarat

A practical buyer’s guide to understand real-world price factors, capacity selection, feature trade-offs, and total cost of ownership for hydraulic shears in Gujarat. Curated by OMAXE Machine Tools India Pvt. Ltd., Ahmedabad.

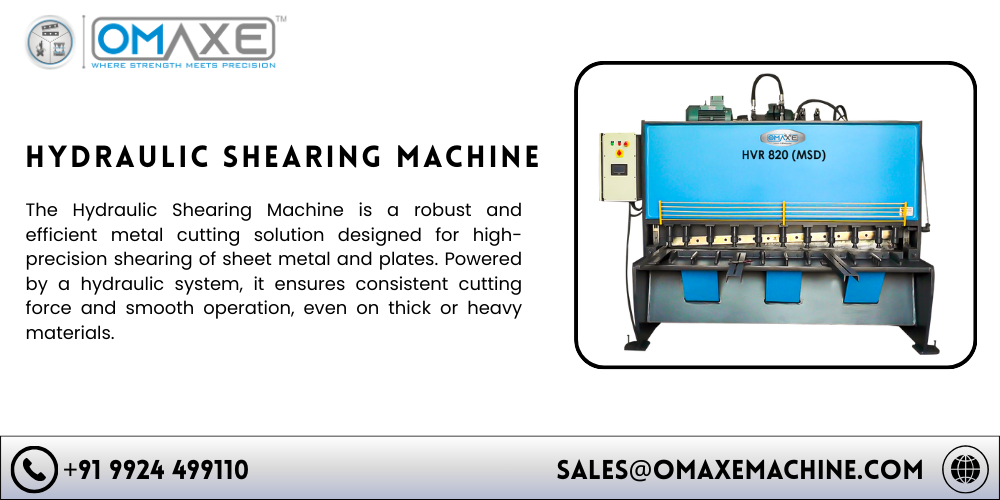

What is a Hydraulic Shearing Machine?

A hydraulic shearing machine uses a hydraulic power pack to apply consistent cutting force on sheet metal and plates. With adjustable blade clearance, rapid back-gauge movement, and vibration-damped frames, it delivers smooth cuts across mild steel, stainless steel, and aluminum—ideal for fabrication, automotive, construction, and general engineering.

Common Capacity Options & Specs (Indicative)

Use this matrix to shortlist. Final sizing depends on material grade, thickness tolerance, and duty cycle.

| Model Range | Max Thickness (MS) | Max Length | Back-Gauge | Blade Material | Controller |

|---|---|---|---|---|---|

| Light Duty | 4–6 mm | 1250–2500 mm | Manual / Motorized | HCHCr / 18% Cr | Manual / DRO |

| Medium Duty | 6–10 mm | 2500–3200 mm | Motorized (±0.1–0.2 mm) | HCHCr / D2 | NC |

| Heavy Duty | 10–20+ mm | 3200–6100 mm | Servo / Ball Screw | D2 / Special Alloy | NC / CNC |

Tip: Choose capacity with a 15–25% headroom over your typical thickness to protect blades and frames.

Hydraulic Shearing Machine Price in Gujarat — What Actually Drives It?

Market prices vary across models and configurations. These are the practical cost drivers that matter in Gujarat:

Why Choose a Hydraulic Shear?

- Stable cut quality with reduced burrs and minimal deflection.

- Adjustable rake angle and blade gap for different materials.

- Quiet, low-vibration operation and improved operator safety.

- Faster setups with back-gauge presets and stroke control.

- Lower blade wear due to optimal clearance settings.

- Consistent results across long shifts and heavy workloads.

- Upgradeable to NC/CNC for batch accuracy and repeatability.

- Proven reliability for fabrication and OEM parts production.

Industries in Gujarat Using Hydraulic Shears

We regularly serve Ahmedabad, Vadodara, Rajkot, Surat, Jamnagar, and across India.

Hydraulic vs Mechanical vs NC/CNC Shear

| Type | Best For | Accuracy | Speed | Notes |

|---|---|---|---|---|

| Hydraulic (Swing-Beam / Guillotine) | Varied thickness, quality-critical work | High | High | Stable cut, adjustable gap; ideal for MS/SS/Al. |

| Mechanical | Thin sheets, limited budget | Medium | Very High | Less flexible on thick plates; higher noise/vibration. |

| NC/CNC Hydraulic | Batch production, tight tolerance | Very High | High | Servo back-gauge, recipes, better repeatability. |

Buying Checklist (Price-Saving Insights)

- Define maximum thickness/length and choose 15–25% capacity headroom.

- Confirm material mix (MS, SS 304/316, aluminum) and tolerance needs.

- Decide on back-gauge: manual, motorized (DRO), or servo NC/CNC.

- Ask for blade material/spec and sharpening interval guidance.

- Verify safety (guards, interlocks, emergency stops, electrical compliance).

- Plan power, foundation, and handling (unloading/placement) in advance.

- Check warranty, preventive maintenance, and spare parts availability.

Maintenance & Safety (Reduce Total Cost of Ownership)

Routine Tasks

- Check hydraulic oil level/cleanliness; follow OEM intervals.

- Inspect hoses, seals, and cylinder leaks; tighten as needed.

- Clean scales/rails; verify back-gauge repeatability.

- Maintain blade sharpness; log cut counts between sharpenings.

Operator Safety

- Use finger guards, foot pedal with proper interlocks.

- Train on blade-gap/rake adjustments before shift runs.

- Follow lockout/tagout during maintenance.

- Keep PPE compliance (gloves, eyewear, safety shoes).

Why OMAXE Machine Tools India Pvt. Ltd. (Ahmedabad)

With 25+ years of experience, 350+ models, and 200+ successful installations, OMAXE designs and manufactures hydraulic shears with robust frames, reliable hydraulics, precision back-gauges, and responsive service support.

FAQs: Hydraulic Shearing Machine Price in Gujarat

Get Expert Guidance

Need help selecting the right CNC Press Brake for your bending application? Our team at OMAXE Machine Tools India Pvt. Ltd. is available to assist you with technical guidance, model selection, and customization requirements.

Vanch Road, Daskroi, Dhamatwan, Gujarat – 382435

Top 20 Primary Keywords – Hydraulic Shearing Machine

Explore high-ranking search terms for OMAXE Machine Tools India Pvt. Ltd. related to Hydraulic Shearing Machines. These internal keyword links enhance on-page SEO and help visitors navigate directly to key product pages.